i-doit at the Max Planck Institute for Plasma Physics

ASDEX Upgrade: Fusion research made in Europe

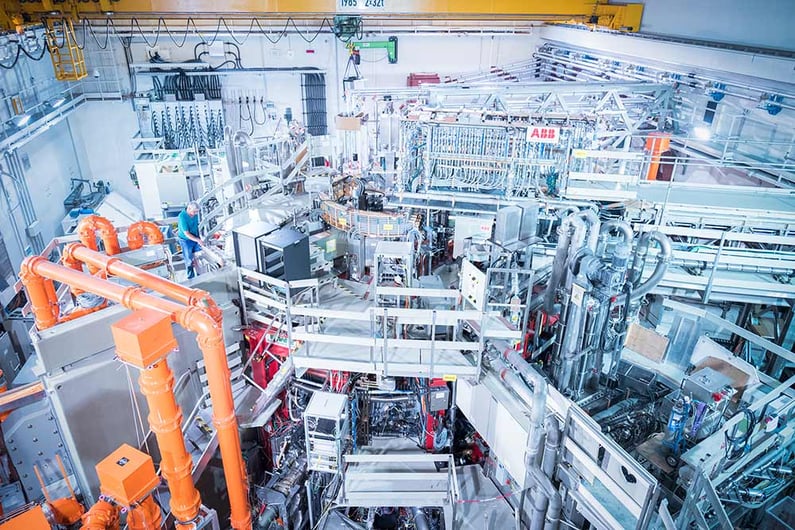

The Max Planck Institute for Plasma Physics is one of the leading and largest institutions for research into energy production from nuclear fusion. Outstanding global projects such as Wendelstein 7-X in Greifswald were developed by its more than 1100 employees.

Another project of the Max Planck Institute is "ASDEX Upgrade" (Axial-Symmetric Divertor-EXperiment). Alongside Wendelstein 7-X, this facility is one of the largest German test facilities. More than 40,000 plasma ignitions have been carried out here since 1991. ASDEX Upgrade is used to investigate aspects of plasma physics that are relevant to the ITER fusion reactor currently under construction and its later successor DEMO. The experiments carried out here are intended to answer questions about the future generation of electrical energy from the fusion of atomic nuclei under power plant-like conditions.

The data from this facility is quite impressive. With a diameter of 5 meters and a weight of 800 tons, a fusion plasma with a heating capacity of up to 27 megawatts is brought to a temperature of 100 million degrees in this facility.

Since the plant was built, the power supply and auxiliary heating systems as well as the measuring and control equipment have been continuously expanded. This has resulted in an enormous amount of equipment and systems available to the scientists. As the number of systems inevitably increased, so did their complexity. It became increasingly difficult to maintain an overview of the individual devices, their arrangement and dependencies. This led to the decision to introduce a new inventory system. The choice fell on i-doit.

Organization: Max Planck Institute for Plasma Physics

Department: ASDEX Upgrade, Basic Research Plasma Physics

Employees: approx. 1,100

Built: 1991

Number of experiments carried out: Over 40,000

What led to the decision for i-doit?

Much of the project's data could have been recorded in Excel. However, such tables are one thing above all: static. Maintaining the data efficiently and, above all, automatically is only possible with enormous effort.

Another disadvantage: the life cycle of a system, all changes, innovations and updates are difficult to map with Excel. It was therefore clear that a database solution would have to be used in order to meet the high documentation and automation requirements.

The solution

While various inventory solutions were being examined, the team at the Max Planck Institute realized that the problems to be solved were also known in another area: IT. It quickly became clear that a configuration management database would be the appropriate solution. As part of an evaluation, various CMDB solutions were put through their paces. i-doit was able to convince across the board. Ultimately, the high level of flexibility, expandability and the many integrated interfaces were the decisive factors.

These criteria were important for the decision:

-

Scalability of database size and number of objects

-

Multilingual (German and English)

-

Browser-based and therefore largely independent of operating systems or the installation of special software

-

On-site installation (on-premise)

-

Data is stored on a local server, not in a third-party cloud

-

Single sign-on with central employee ID card

-

Hierarchical authorizations for read, write and access prevent unwanted manipulation of data records

-

Data backup and archiving with recording of changes

-

Regular updates with new functions, bug fixes and change history, also taking user suggestions into account

-

Good and fast support

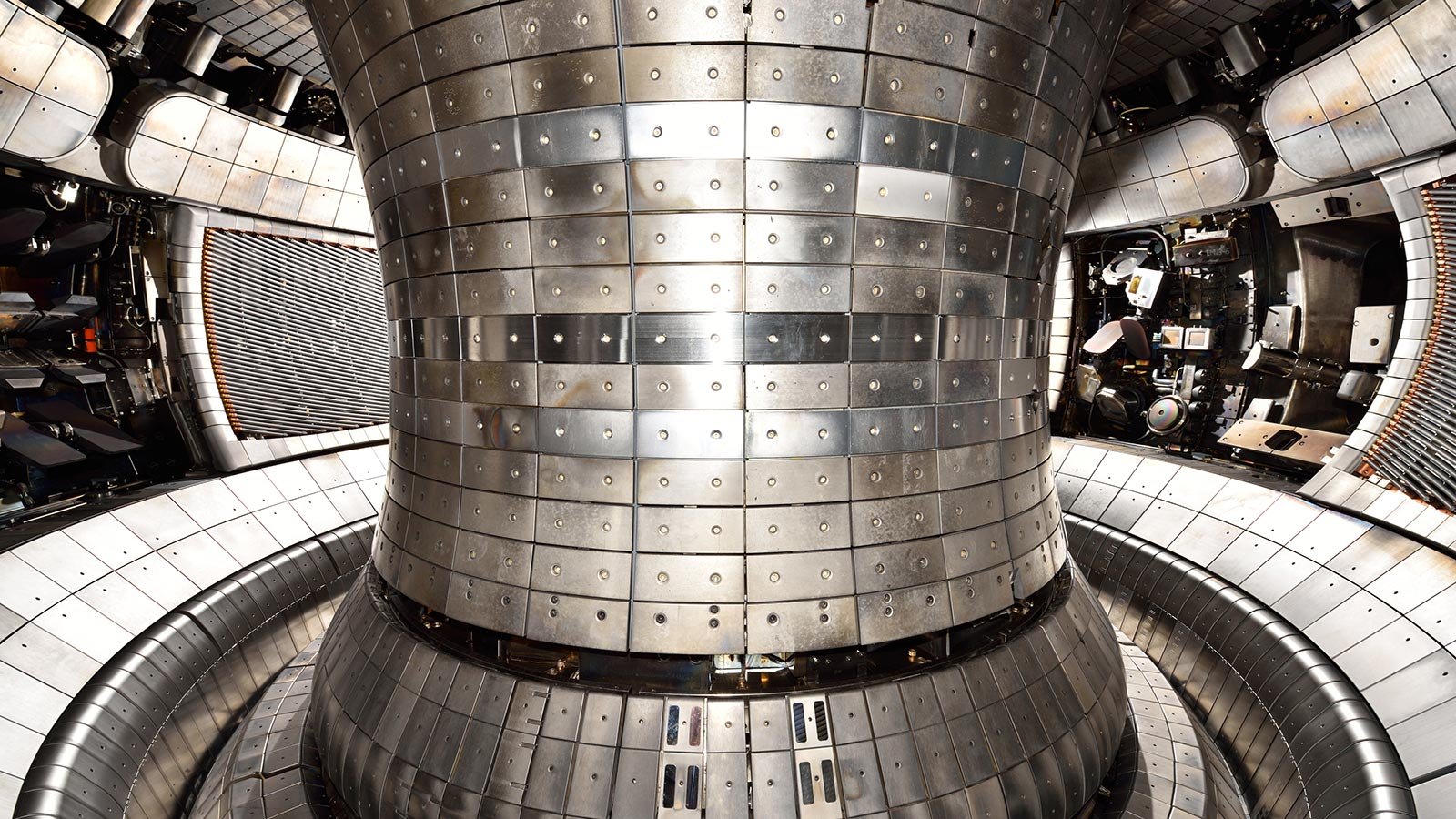

ASDEX Upgrade fusion device: plasma, divertor, plasma vessel (with numerous observation nozzles), main magnetic field coils and their support structure. (Graphic: MPI for Plasma Physics, Mathias Dibon)

Source: https://www.ipp.mpg.de/bilder/asdex

Installation and commissioning of i-doit

For the operation of i-doit, the installation on a separate server was chosen. Access control was implemented with single sign-on so that employees could use their usual access data. Thanks to i-doit's granular rights system, all of the Max Planck Institute's requirements could be met in order to control access to information as needed.

The introduction of i-doit at a research facility such as the ASDEX upgrade is not a classic IT project. The IT-oriented concept of i-doit had to be adapted, whereby the software was able to prove its flexibility. The main focus here was on recording diagnostic units, control cabinets, sensors and actuators. Separate object type classes were defined in advance for these assets and created via the WebGUI.

Before i-doit was used productively in the Torus hall, over 100 well-documented devices were used as test objects. The data for these devices was available in spreadsheet documents that could be imported as CSV files in a single step.

There were no such documents for the diagnostic devices and the installations in the Torus hall. The missing data was and is added manually. To ensure a uniform structure and naming of the objects, only one employee is currently authorized to create new objects. The detailed information on the individual devices, on the other hand, is collected by the "owners" in lists and then imported into i-doit via mass import.

Recording infrastructure and services

The relationship concept of the i-doit CMDB is also used for the ASDEX upgrade. A diagnostic unit is defined as a location via a local relationship to which the components "control cabinet" and the associated "laser" are linked.

In addition to these local relationships, functional dependencies (services) are also mapped as they are known from the IT environment. Certain services are only available if all the components involved are working. In the ASDEX upgrade, the evaluation of video material is a very important service. This service is only available if all components from the camera head to the evaluation processor are working smoothly.

A special feature of the functional dependencies is that one component can be used in several services. By using the i-doit CMDB, the responsible employees can now see at a glance which components are affected by the maintenance of a system, for example. They are able to develop preventive and corrective measures.

Requirements for cabling and recording measurement signals

In addition to the pure recording of the infrastructure, the signal paths are an important criterion in research. In a complex system such as the ASDEX upgrade, hundreds of sensors are used, e.g. temperature, pressure and flow meters. Traceability is essential here.

Information about which sensor is sending its signal to which system or signal transmission room must be available at all times. The signals are isolated, filtered, amplified and then digitized to various recording, control and protection systems.

i-doit offers the option of documenting the cabling for each asset. A distinction is also made between inputs and outputs. This allows the entire measurement chain and its cabling to be mapped true to the original.

Even the cables used are clearly identified by assigning a cable number. At the Max Planck Institute, the final destination for the measurement signal (scientific database) is also created as a virtual object. This makes it possible to show where the data is finally stored after processing.

The i-doit add-on Floorplan is used as additional support. The transformers and other devices are precisely placed on each floor to provide a quick overview of each floor.

View into the plasma vessel of the ASDEX Upgrade fusion facility (2015) (Photo: MPI for Plasma Physics, Volker Rohde) Source: https://www.ipp.mpg.de/bilder/asdex

Assignment of responsibilities

Given the large number of technical devices, responsibilities must be defined. The existing standard category "Contact assignment" is used for this purpose. This category is used to enter operators and users on the one hand, and those responsible for maintenance and operation on the other. In this case, however, groups rather than individual users are linked as contacts.

This solution offers a decisive advantage. If there is a change of personnel, the administrative effort is reduced. Users are simply removed from the relevant group. The new employee is added. However, the groups and their assignments do not need to be changed.

In day-to-day operations at ASDEX Upgrade, each group decides for itself how extensively it documents information about components. The following principle applies here: the more relevant information is available, the easier it is to analyze the causes of any problems that arise. This in turn is in the interest of the groups.

A positive side effect: when recording the systems in the Torus hall, it was found that the responsibility for around 350 objects was not clear. It is now possible to identify contact persons for these objects and clarify their further use. The introduction of i-doit thus contributes to greater transparency.

The future of i-doit in the ASDEX upgrade project

Following the successful rollout of the i-doit CMDB, key information about the existing systems is available centrally. Thanks to the CMDB, all employees have standardized access to the parameters and status of systems. Links, maintenance intervals and responsible contact persons are visible at a glance, as are overview diagrams and system images.

In fact, i-doit was initially only intended for documenting the electrical components in the Torus hall. However, the system has now been expanded to cover all transformers at the Garching site. Furthermore, i-doit is used to record all irradiated components that leave the torus hall. This supports conformity with existing radiation protection requirements.

The greatest challenge in the future will be the continuous maintenance of the objects created. Missing and new components must be created and new services implemented. However, this challenge is also the greatest opportunity. The introduction of the new CMDB offers a unique opportunity to clarify the status, responsibility and further use of previously unresolved objects.

Overall, the Max Planck Institute rates i-doit as a very useful tool for recording assets, documenting cabling and ports and mapping their services.

Credits: All photos used are from the press portal of the Max Planck Institute for Plasma Physics, Garching